Freyssibar

Freyssibar® system is produced and installed worldwide systems since 2005. The range is engineered to meet all the needs and challenges facing the construction industry, from the most standard cases through to the most demanding applications.

Amzone is now able to offer all the products in the Freyssibar® range, through a dedicated team, and a stock of bars and accessories.

Applications

• Bridges and viaducts

• Marine works • Nuclear plants • Wind turbines

• Oil and gas infrastructure

• Temporary construction systems

• Heavy lifting and handling

• Geotechnical applications

Structures

• Concrete

• Steel

• Masonry

• Timber

FUNCTIONS

• Internal or external prestressing

• Temporary or permanent uses

• Passive or active anchorages

• Re-stressable, removable, replaceable

A CERTIFIED SYSTEM

• European Technical Assessment: ETA 09/0169

• CE Marking: 1683-CPR-0052

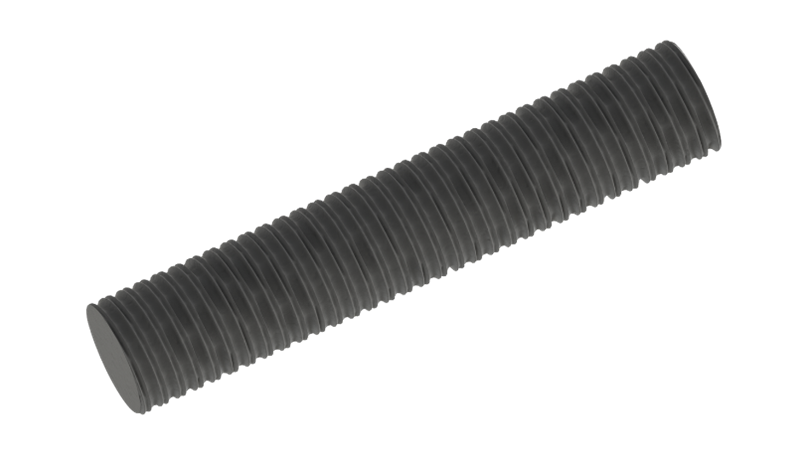

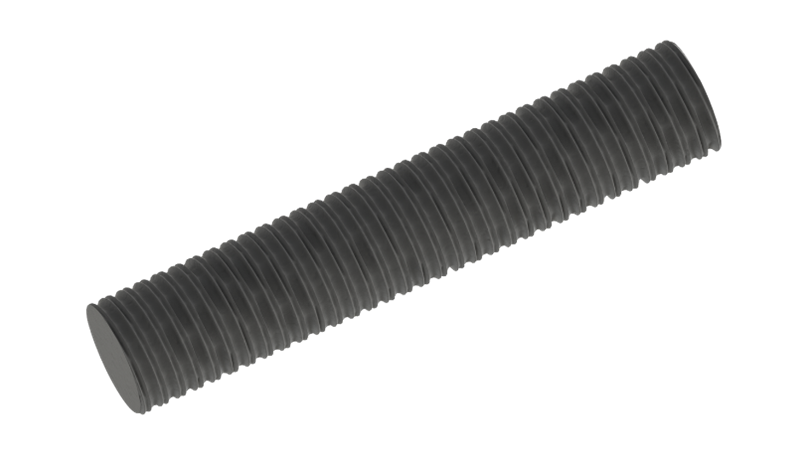

Material | Bar Characteristics |

Utimate Yield Strength | Yield Strength | Elongation at maximum force (Agt) | Elongation at break (A%) | Modulus of Elasticity | Nominal Diameter (D) | Mass per lm | Ultimate Load | Yield Load |

MPa | Mpa | % | % | Mpa | mm | kg | kN | kN |

1030 | 835 | 3.5 | 6 | 170,000 | 26.5 | 4.56 | 568 | 461 |

32 | 6.66 | 828 | 672 |

36 | 8.45 | 1048 | 850 |

40 | 10.41 | 1295 | 1049 |

50 | 16.02 | 2022 | 1640 |

POST-TENSIONING APPLICATIONS

Anchoring Structural elements

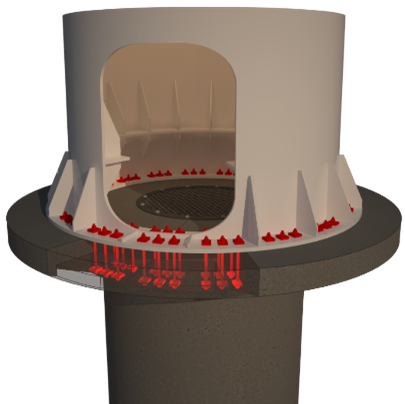

FREQUENT APPLICATIONS: WIND TURBINES/ TOWERS/ANTENNAS

To Create a Stable and long-lasting joint between two Structural elements,

Such as securing steel and concrete opponents, they can simply be tightened

Together with prestressing. The Freyssibar ensured a long-term compression

Joint.

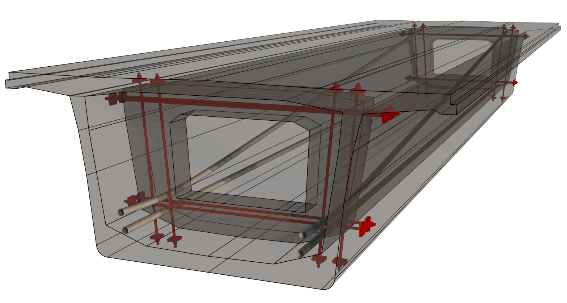

Blisters

FREQUENT APPLICATION: BRIDGE DECKS/ BEAMS / SLABS

When fitting additional prestessing tendons to existing structures,

Attachments(sheaves) and deviation points need to be created. The anchoring systems for the neds of the tendons are fitted to the heaves, while the main runs are guided through the existing structure that needs structure that needs strengthening by generating a traverse nailing force that creates the necessary friction between each sheaf and the structure.

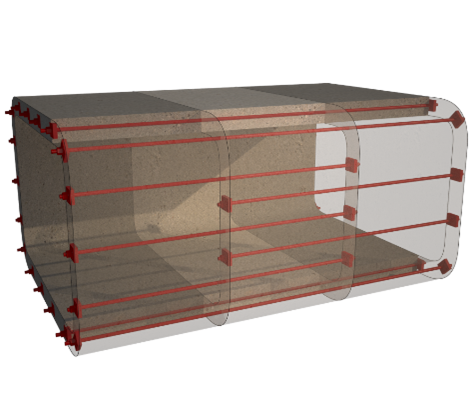

Assembling precast elements

FREQUENT APPLICATION: VIADUCTS BUILT WITH LAUNCHING GANTRIES/BRIDGE PIERS/FLOATING CAISSONS/3D-PRINTED BUILDINGS

Whether for temporary or permanent applications, the Freyssiber system offers a simple and effective solution for assembling precast concrete elements with prestressing bars.

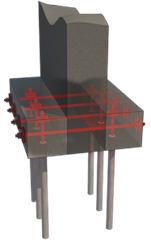

Connection with a foundation

FREQUENT APPLICATION: BRIDGE PIERS / COLUMNS

Micropiles and prestressing bars can be combined to create a simple and effective foundation for an existing or prefabricated structure.

The prestessing bars create a friction joint between the structure and the sole plate, which is built on micropiles, without any need for a complex and dense rebar arrangement.

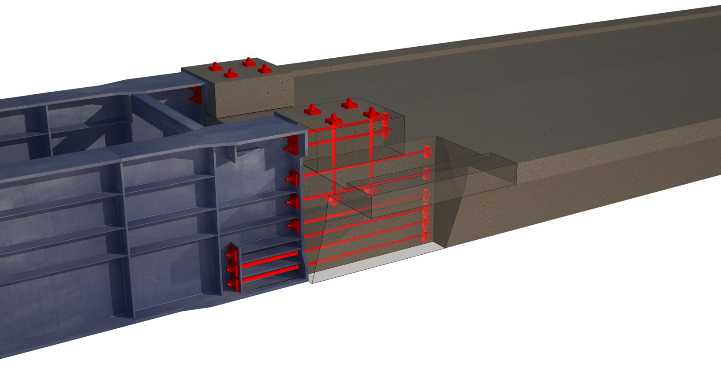

Fixing launching noses

FREQUENT APPLICATION: INCREMENTALLY LAUNCHED BRIDGES/ DE-LAUNCHING

Fixing a nose to deck requires the use of high prestressing forces in a confined space. Designers are often faced with the problem of how to arrange the bars in the available space. The wide range of possibilities offered by the Freyssibar systems makes this process much easier since they improve the forces applied to each assembly while reducing the number of bars

Prestressed Structures

FREQUENT APPLICATIONS: BRIDGES/DAMS/BUILDINGS/ CIVIL ENGINEERING STRUCTURES

The Freyssibar and Freysibar+ systems are widely used to create prestressed structures, especially for repairs and strengthening.

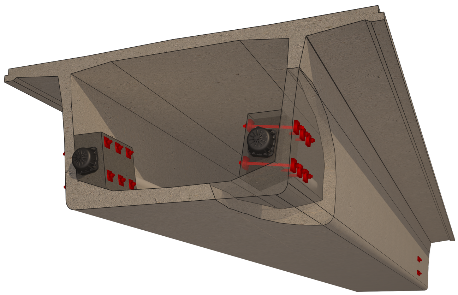

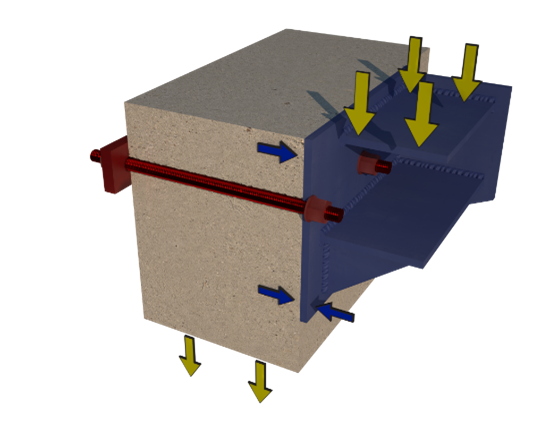

Fixing Brackets

FREQUENT APPLICATIONS: JACKING STRUCTURES/WIDENING PIER CAPS AND DECKS/ BALCONIES

The principle for transferring the load from a bracket to a structure through friction can be achieved with a Freyssibar or a Freyssibar + system. During this process, controlling the applied forces is essential for the joint’s performance and safety of the structure.

GEOTECHNICAL APPLICATIONS

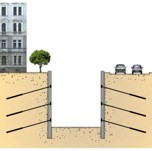

Excavations

The anchors ensure the stability of the soil and allow for large and deep excavations. They are often temporary, as the long-term stability of the ground will be ensured by the structure built in the excavation (car parks, basements, etc.).

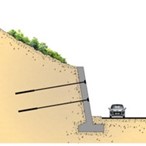

Slope stabilization

The anchor is the essential element that transmit forces from a retaining wall to the ground and ensures the overall stability.

Dams

Vertical anchors are generally pre-stressed and improve the stability of dams, while reducing water ingress along the contact line with the rock.

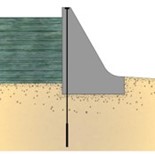

Quay walls

Ground anchors are generally used to improve the stability of an existing quay wall.

Underground structures

Anchors ensure the stability of galleries by balancing the forces of the ground. This technique applies to mines and tunnels.

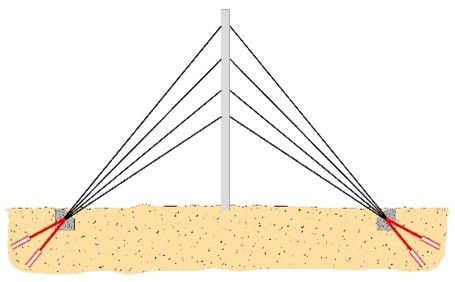

Anchoring structures

Vertical anchors provide an effective link between the foundation and the ground, while limiting the effects of fatigue when pre-stressed. The anchors can be used for towers, radio masts, wind turbines, etc.

Hydraulic uplift loads

Anchors are used to hold structures in place that are subject to high water uplift pressure and therefore allow structures to be built in underwater areas by compensating for Archimedes’ principle.

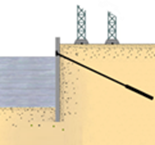

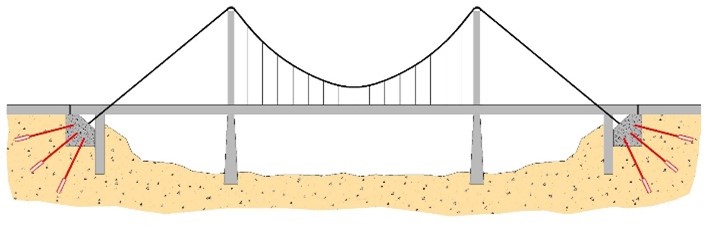

Anchoring cables

Anchoring a cable anchor block to the ground by means of pre-stressed ground anchors makes it possible to limit or cancel the movements, and therefore the fatigue effect.